Wear plates are expendable items that are used to prevent excessive wear or damage to expensive equipment. Wear plates are used to prevent damage to the main machinery due to abrasion or impact and to increase the life of the machine. The harder the plate that is used, the longer it will last in service, but there are trade-offs. For some parts, you will need a softer material that is intended to wear out before your primary surface. There could be an easy and cost-effective fix to the problem. We can customise to incorporate these wear plates when not in the original equipment design.

Examples of machines or components that might require wear plates or liners are:

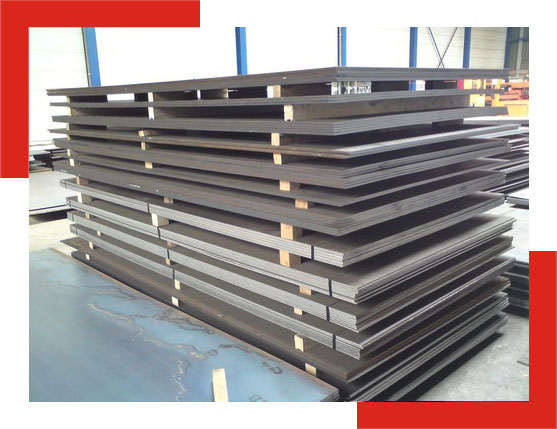

Specifically designed and manufactured by, our wear plates comprise a base plate of construction steel and a wear resistant coating applied by arc welding, offering exceptional resistance to abrasive wear. Our wear plates & liners are distinguished by their high quality, consistency, functionality and adaptability.

- Crushers

- Shredders

- Casting equipment

- Steel and aluminium mill equipment

- Heavy earth moving and lining equipment